This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping us to understand which sections of the website you find most interesting and useful.

About Us

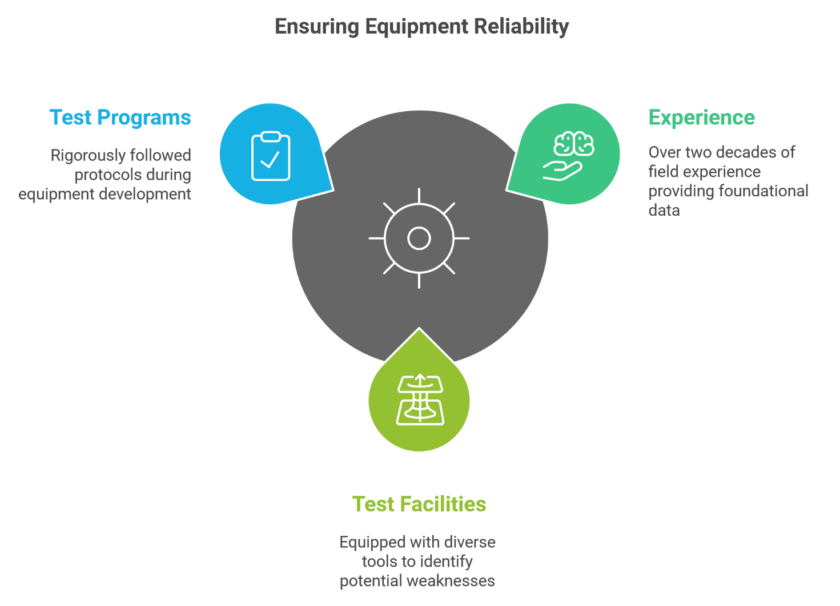

Creowave was founded in 2004 to help customers reach their targets. At the time, the accuracy and reliability of Multiphase metering needed a step-improvement. The result was a high-precision metering electronics, which can deliver accuracy never seen before in the industry.

This, combined with verified life expectancy of more than 30 years in challenging subsea conditions, gives us unique experience on how to make the high performance electronics with acceptable cost levels.

Since then, our experience with building reliability into high performance has taken us to a journey of helping the customers to leverage on the availability of modern communication in difficult field environments. With our products, our customers are one step closer on meeting their Net-zero targets on emissions of greenhouse gases.

All under one roof

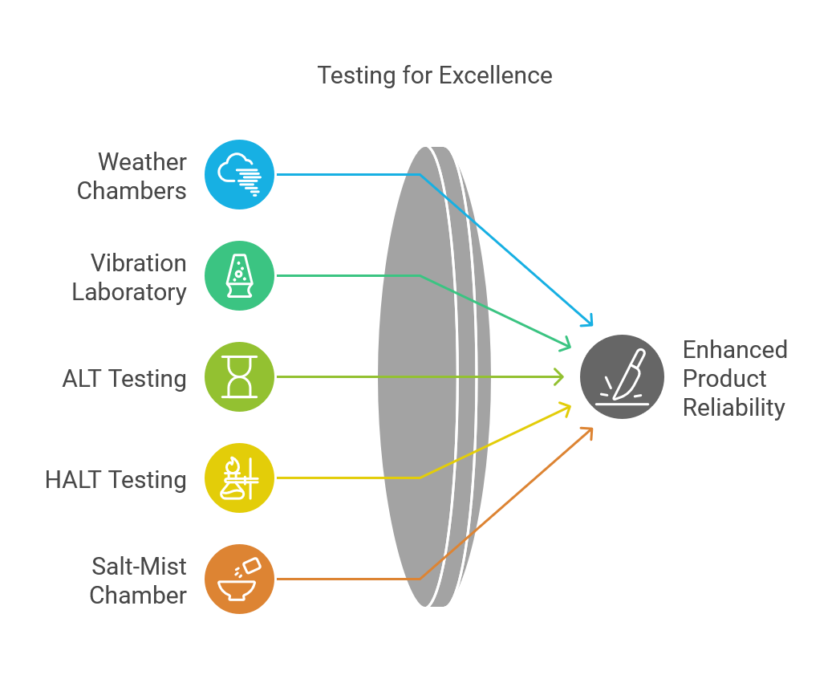

During the years in operation, we have continously invested into people and equipment, to be able to improve our expertice on providing reliable solutions for our customers. Today, we have sophisticated test equipment on all fields of electronics reliability – in house.

Those include the weather chambers, Vibration laboratory, ALT- and HALT testing facilities and the latest is the salt-mist test chamber to simulate the highly corrosive environments in the field. These are all essential steps on building and maintaining the reliability of the products.

Reliability in everything

Uncertainty has been the key word in the world development over the last years. To be able to secure the deliveries to the customers, Creowave decided to invested into shortening the supply chain and reducing the effects due to different kinds of potential challenges in supply chain, regardless if they are man-made or coming from the nature.

We have secured the critical items in inventories and invested in the production line of electronics, so that everything we do, can be managed from the supply chain-point-of-view to secure the deliveries into customer projects – regardless of the surprices in the global environment. And this also helps us to prevent unwanted changes in the manufacturing process – thus maintaining steady quality in operations.